34 ppap process flow diagram

8.6 Requirement 5: Process Flow Diagram. 14. 8.7 Requirement 6: Process Failure Mode and Effects Analysis (PFMEA). 14. 8.8 Requirement 7: Control Plan.64 pages

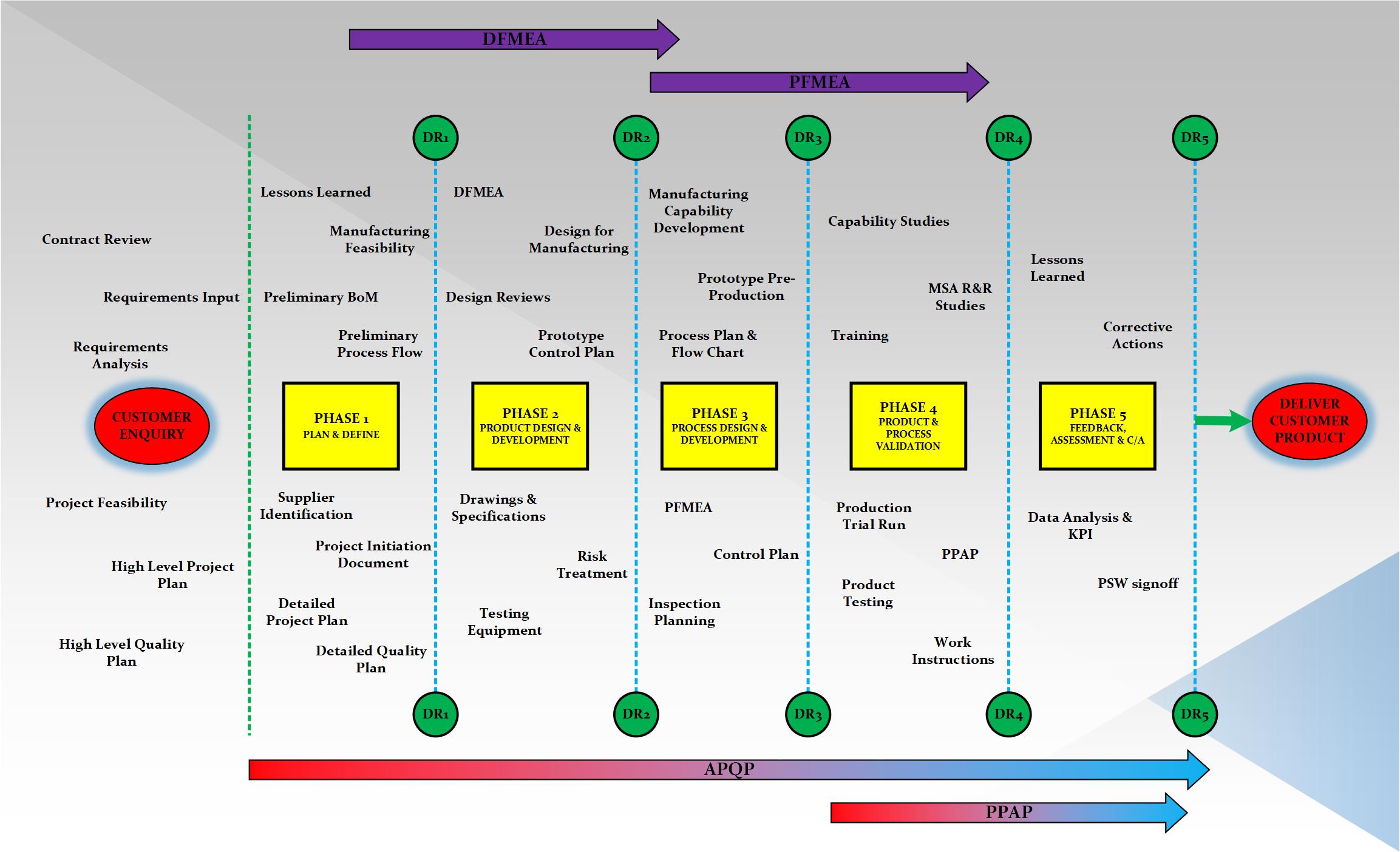

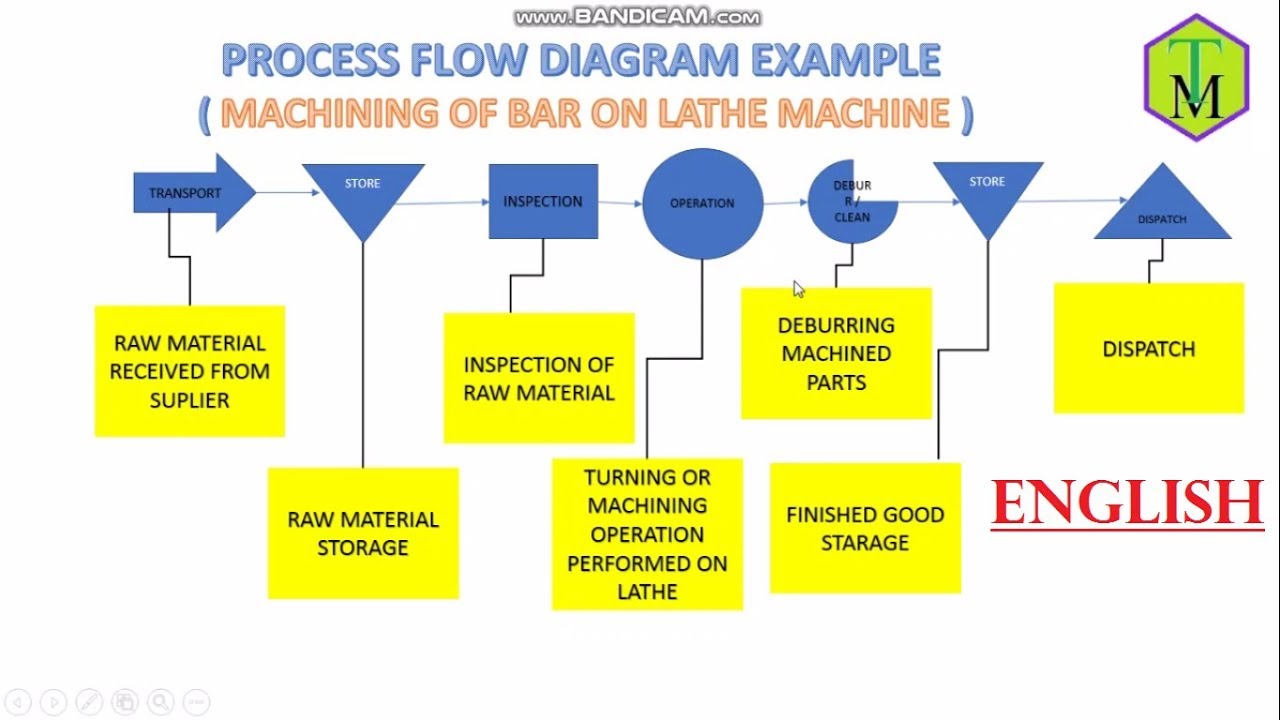

The Process Flow Diagram outlines the entire process for assembling the component or final assembly in a graphical manner. The process flow includes incoming material, assembly, test, rework and shipping. Process Failure Mode and Effects Analysis

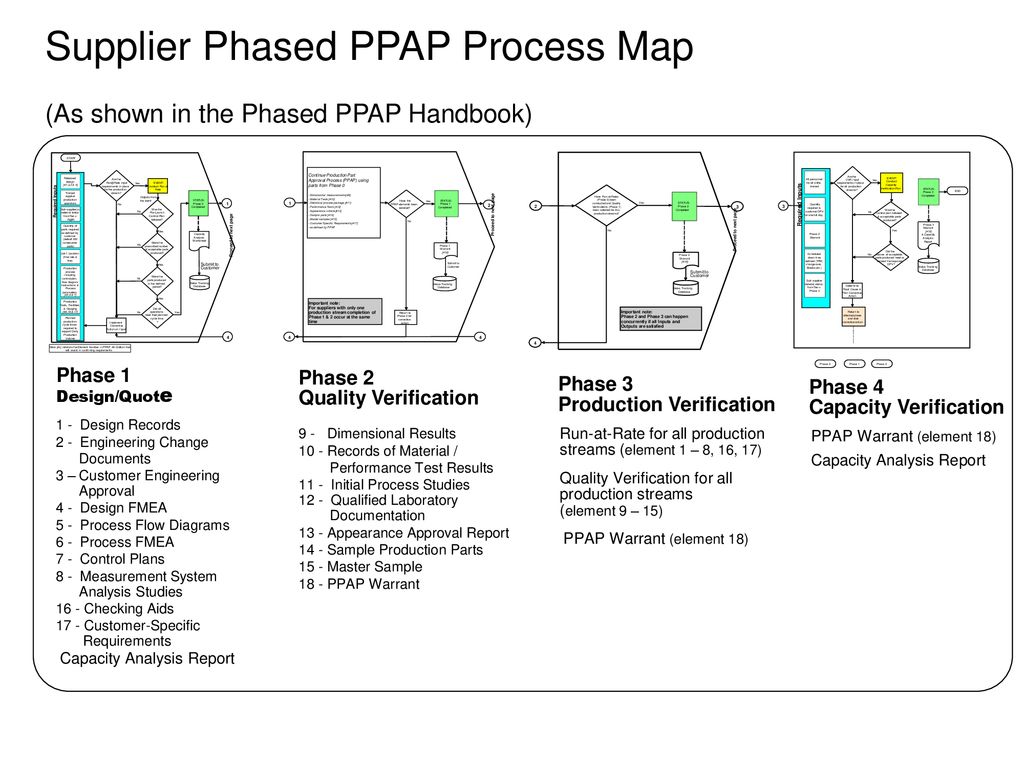

In the AIAG 4th edition of the PPAP book page ii shows a PPAP Process Flow Diagram in a pictorial format - and please remember the AIAG is a suggested set of guidlines to follow and in some cases are fully accepted by our customers and in other cases they are less interested in having a specific format.

Ppap process flow diagram

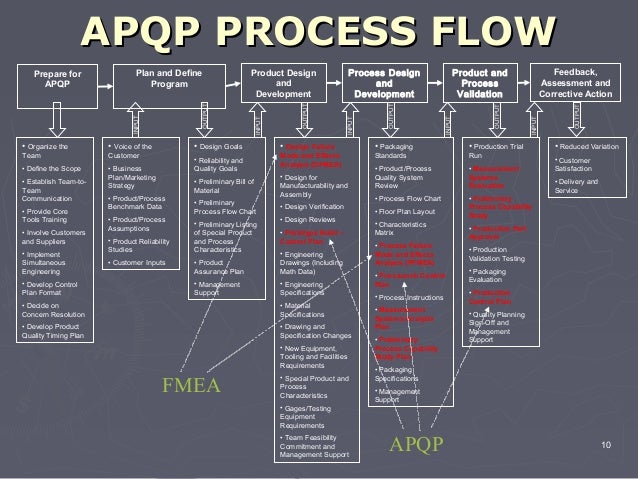

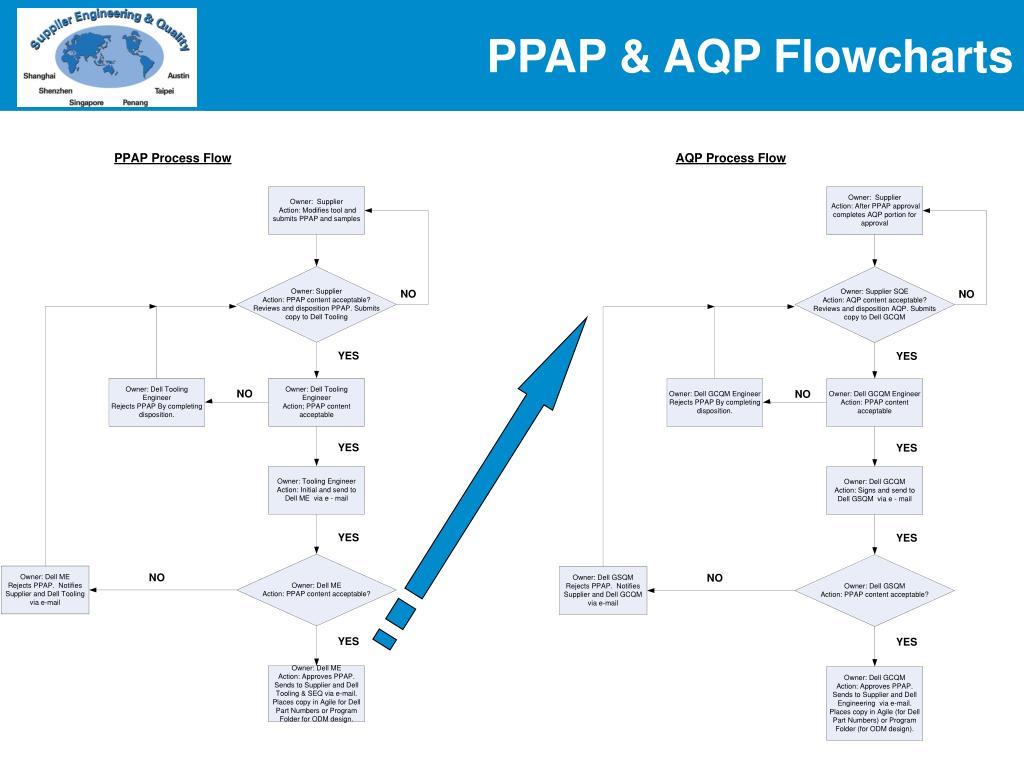

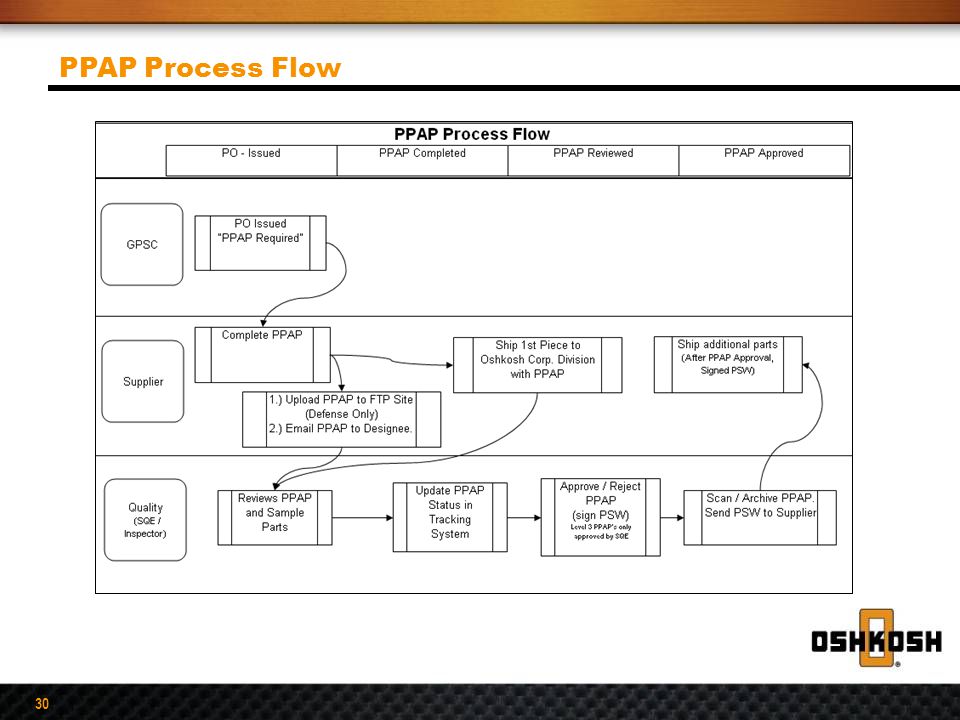

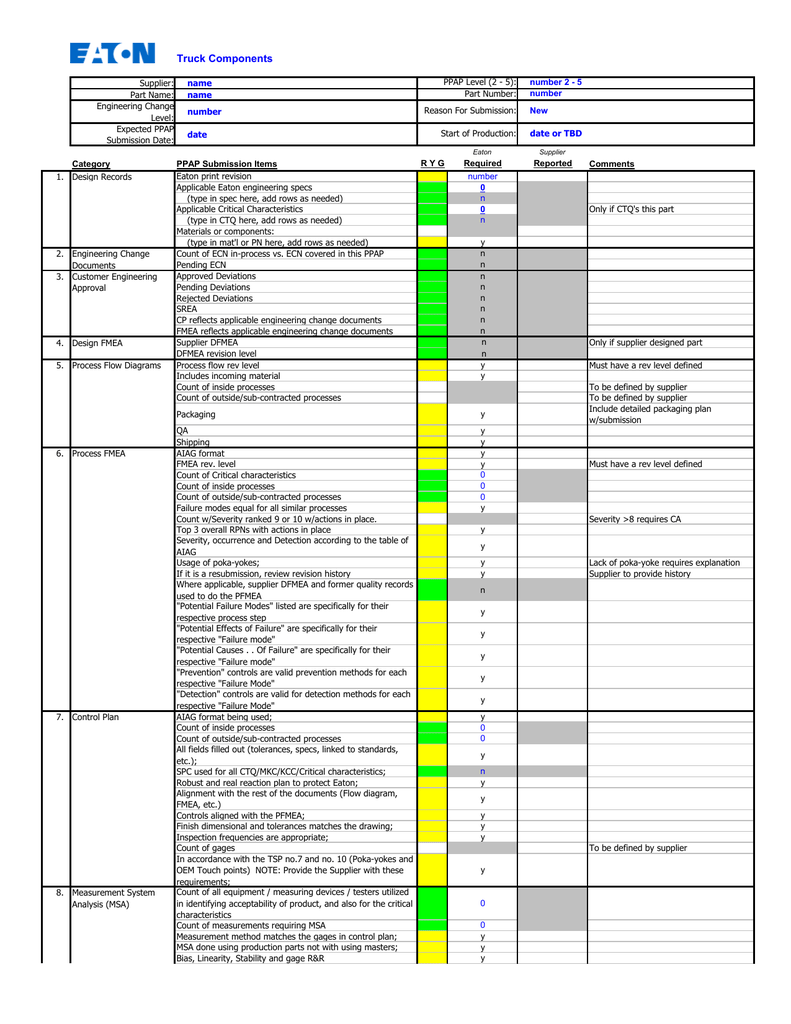

This procedure defines PPAP related terms and all aspects of the PPAP process, including when a PPAP submission is required, what the general PPAP submittal requirements are and what the possible outcomes and consequences of a PPAP submission are. In addition to the description provided in the Manual’s sections, PPAP process flow charts are ...

Element 3 Process Flow Diagram The purpose of the Process Flow Diagram is to document the steps required in the manufacturing of the part. The Main process steps must match both the Process Failure Mode & Effects Analysis, and the Control Plan. The Process Flow should include the entire process, from Receiving through Shipping.

PPAP Assessment www.quality-one.com Page 4 of 15 with the Design Record, FMEAs, Control Plan, Work Instructions and ALL APQP documentation. Process flow diagrams for “families” of similar parts are acceptable if

Ppap process flow diagram.

Oct 1, 2021 — PPAP PROCESS FLOW CHART . ... Process Flow Diagrams must: . ... The Supplier must have a process flow diagram in a format that clearly ...29 pages

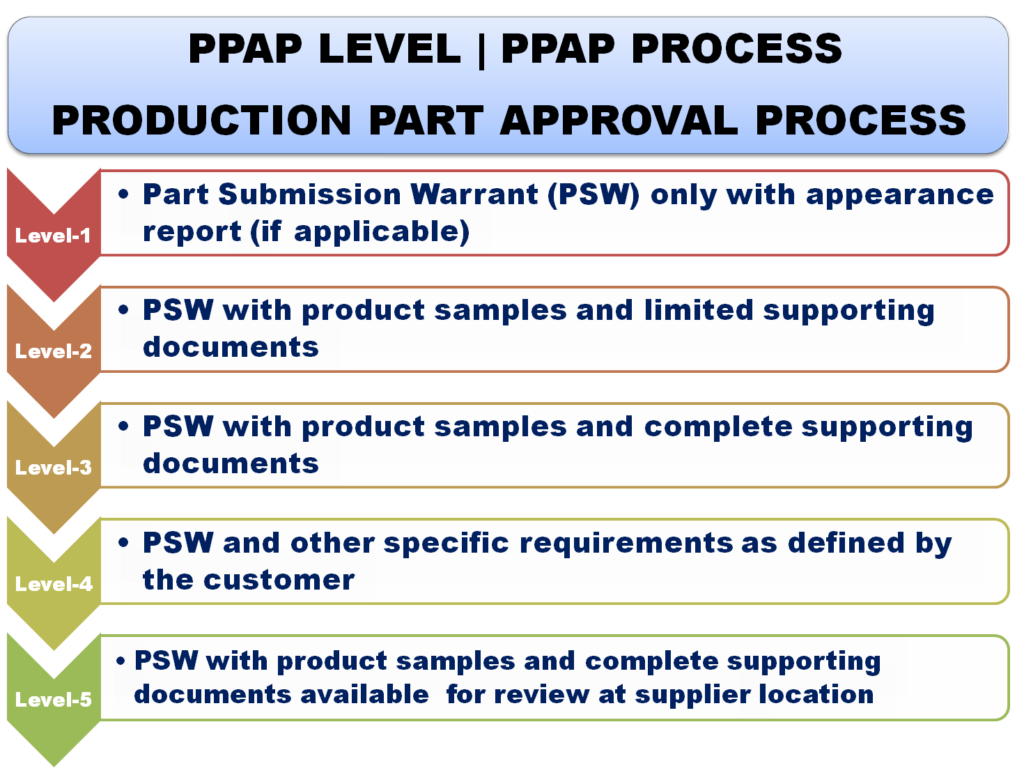

Production Part Approval Process (PPAP) is used in the automotive supply chain for establishing confidence in suppliers and their production processes.Critical elements of the... · PPAP approval · PPAP elements

The Production Part Approval Process (PPAP) is a standardized process in the automotive and ... Process Flow Diagram, also known as a process flow chart, ...26 pages

Process Flow Diagram, also known as a process flow chart, shows the document and clarifies all steps required in the manufacturing of the part in question. The process flow diagram must match both the control plan and the Process Failure Mode and Effects Analysis (PFEMA). The process flow diagram must include all of the main steps in the processing of the part and also all offline activities ...

Production Part Approval Process (PPAP) Flow Chart. Identify PPAP. Requirements at. APQP/Customer. Purchase Order. Fail Safe. Update IML Tools SO.1 page

The purpose of the Production Part Approval Process (PPAP) is: ... Process Flow Diagram 7. PFMEA 8. Control Plan 9. Measurement Systems Analysis (MSA) 10. Dimensional Results 11. Material, Performance Test Results 12. Initial Process Study (Cpk) Capability Studies

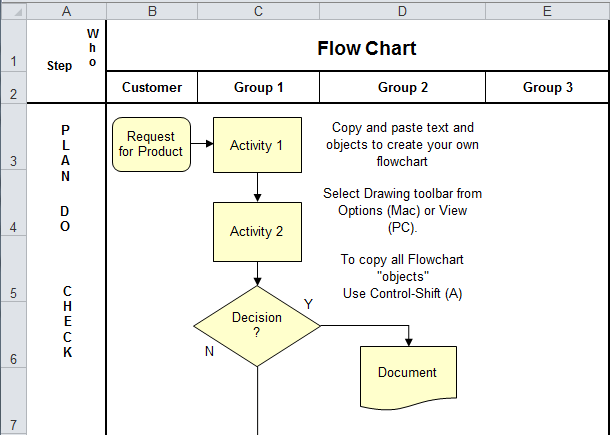

5. Process Flow Diagram Y E S N O Is the Process Flow Diagram legible and in a format that can be understood by the Customer? Are product references aligned to the customer submission? I.e.: Part number, latest drawing issue, facility references etc. Was the manufacturing process flow chart developed by a cross functional team?

To gain the maximum benefit to your quality management system, you must understand how these two Core Tools work in tandem, by developing flow charts, process ...

PPAP Element #5: Process Flow Diagram(s) Step by Step designation of the process flow required to produce the referenced product which meets all customer requirements. Provide linkage to PFMEA and Control Plan. Traditional block diagram . May employ “Family” based diagrams.

The Process Flow Diagram shows all the steps required in the manufacturing of the part. It should include all of the main steps in the processing of the ...

Process Flow Diagram PFMEA Control Plan Product-Process Change 4th Design Matrix 4th Bulk Materials Reqts 4th Performance Test Results 4th ... Complete this form and email to your customer organization whenever customer notification is required by the PPAP Manual in Table 3.1. Your customer will respond back with an acknowledgement and may ...

0 Response to "34 ppap process flow diagram"

Post a Comment