39 how to use lock washers diagram

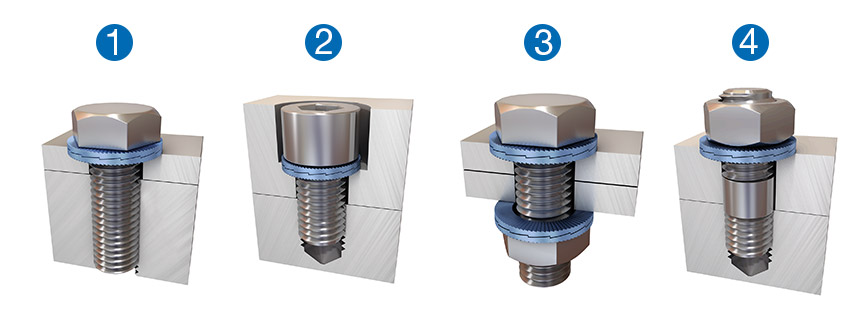

The flat washer can be used on the bolt side, nut side or both. If the assembly calls for o ther types of washers or hardware elements besides these two, they should go on before the lock washer. This way the tension created by the lock washer holds them all in place. It is very important that you do not tighten the lock washer too much.

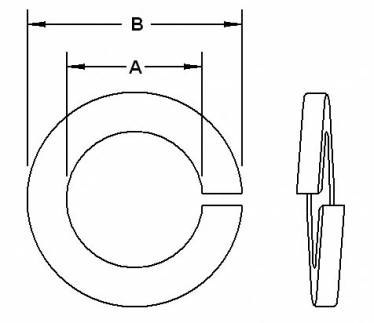

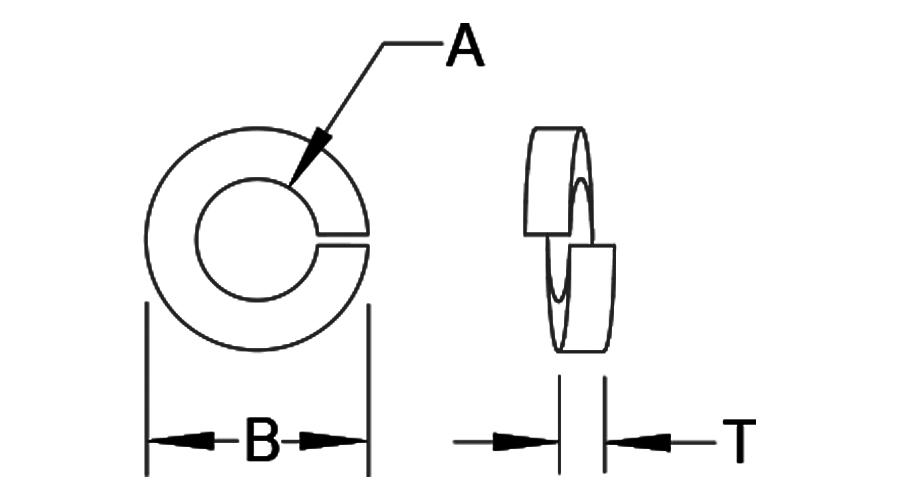

Helical spring lock washers are the most common form of lock washer and are best suited to applications with smaller loads. High-collar lock washers are a kind of split washer. Internal use lock washers have teeth made to bite into the nut/screw head and surface it contacts. They work best on small screws or screws used in electrical grounding.

Diagram illustrates the locking capability of the nuts described in this brochure. The KM(L) lock nuts have been used together with MB(L) locking washers. The lock nuts were tested on a threaded shaft and screwed tightly against a shoulder. No axial load was applied. The grub screws of the KMT,

How to use lock washers diagram

Refer to your washing machine's tech sheet to discover which wires need to be cut. The tech sheet should contain a wiring diagram that indicates which wires are labeled "lock switch" and "lid switch." Most washer's lid lock switches are powered by three or four wires. These are the ones you'll be cutting.

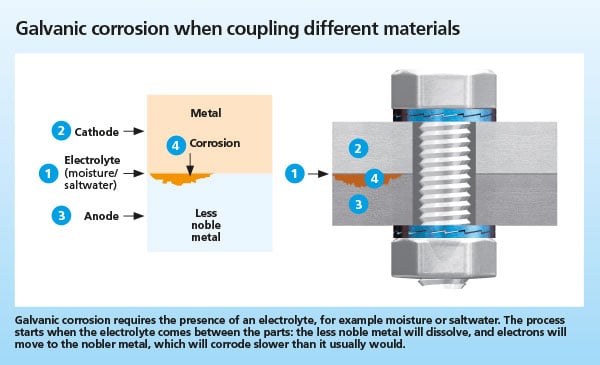

A washer can provide multiple functions, the two most important ones being: 1) proper bearing area to avoid excessive surface pressure; and 2) hard, smooth, and constant-material-composition surface for good preload control. You must analyze the joint design (geometry, materials, and applied forces/moments) and calculate if the washer is necessary.

Differences Between An Internal Tooth Lock Washer & An External Tooth Lock Washer. Tooth lock washers are made with small, sharp teeth formed around the inner hole or outer diameter (O.D.), depending on the type. An internal tooth lock washer has teeth around the center hole, while the external tooth lock washer boasts of teeth around the O.D. Both of these fasteners provide a locking ...

How to use lock washers diagram.

Lock washers are used to prevent nuts, bolts, and screws from vibrating loose, and there are many kinds of lock washers out there. In this video, we discuss ...

2. Lock Washer. This form of lock washer is used to lock the nuts and bolts. These are many forms. Generally, six or more leaves are extended beyond the main diameter of the lock washer. After fixing this washer its leaves are bent on the sides of the nut or bolt. Thus, this washer prevents the nut bolts from getting loose.

washer attached to the armature bolt. use one rubber washer between two metal washers on the armature bolt. the washer assembly must be between the armature plate and the adjustable section of the z bracket. apply the screw locking agent to the armature bolt. do not over tighten. armature must rock to align with the magnet. step 4

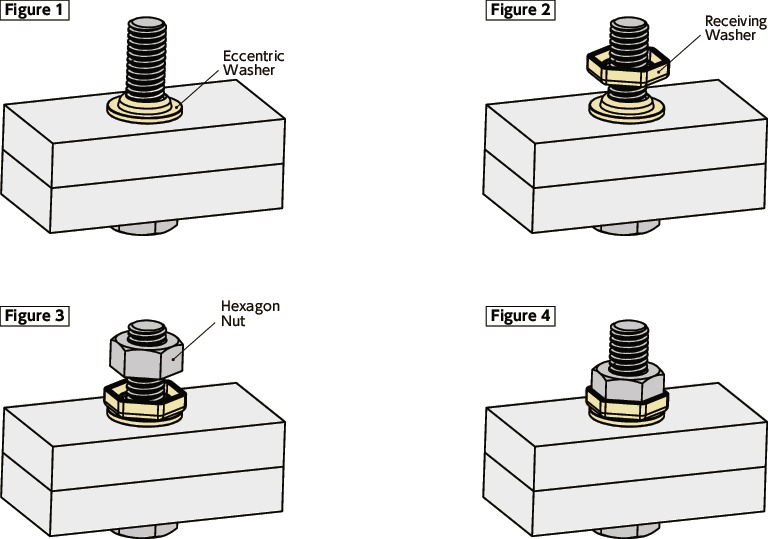

If a lock washer is required, it will be placed on the bolt followed by a second standard washer. Step 3 Align the holes for the joint you are connecting and push the shaft of the bolt through them. The washers should be pressed between the head of the bolt and the material of the joint.

Introduction of Washers. A washer may be a disk formed plate (made of metal, rubber, or plastic) used to garrison the joints from ill-use through adjustment method and to disseminate the load equally below the bolt and nut (i.e., rib fasteners).. Generally, it operates as a spacer or seal. On the opposite hand, Bolt joins two surfaces.It possesses threads and a planate head.

With a lock washer, however, the bolt won't come out. A lock washer will "lock" the bolt in the workpiece's threaded hole. In Conclusion. Flat and lock washers are two of the most common types of washers. A flat washer is a basic washer that's flat on both sides. A lock washer is a semi-coiled washer that's used to secure bolts in ...

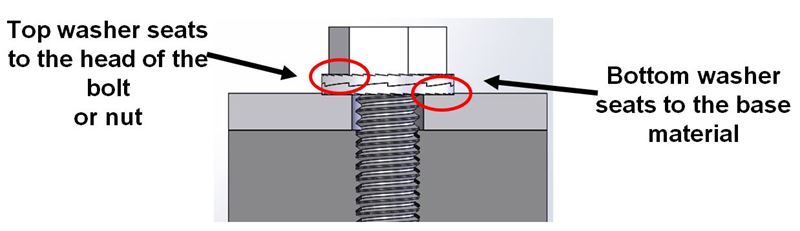

For the same reason, lock washers always go on the nut side to stop the nut moving. Lock washers are almost always used with a flat washer as well. The nut is also often smaller in profile than the bolt head. Not always, but often. The washer helps distribute the pressure that the nut places on the surface of the fastened objects.

Lock washers typically replicate the fasteners head, and offers little improvement over not using one. A hardened flat washer has a larger seating area against the retained component. Although elongation of a retainer reduces applied tensions, disruption of the seat has a similar effect.

Lock Washers: Lock washers are designed to secure fasteners that have a tendency to rotate or lose friction. Although though there are several different types of lock washers and is each designed for use with a particular fastener or application, they all work under the same principle. The washer is designed to exert a load, partially deform, and lock a fastener in place.

Jun 08, 2019 · 3 Ways To Use Lock Washers Wikihow Internal teeth or external. How to use lock washers diagram. Vibration proof locking washers made of other alloys are available as well. So are wedge lock washers for left handed threads. Lock washers are used to keep screws and bolts from loosening especially as a result of vibration or changes in temperature.

Tooth‐Lock Washer as follows: "3.1 The tooth‐lock washers covered in this Standard are intended for general applications. The tooth‐lock washers serve to increase the friction between the screw and the assembly. Internal tooth‐lock washers are preferred where it is

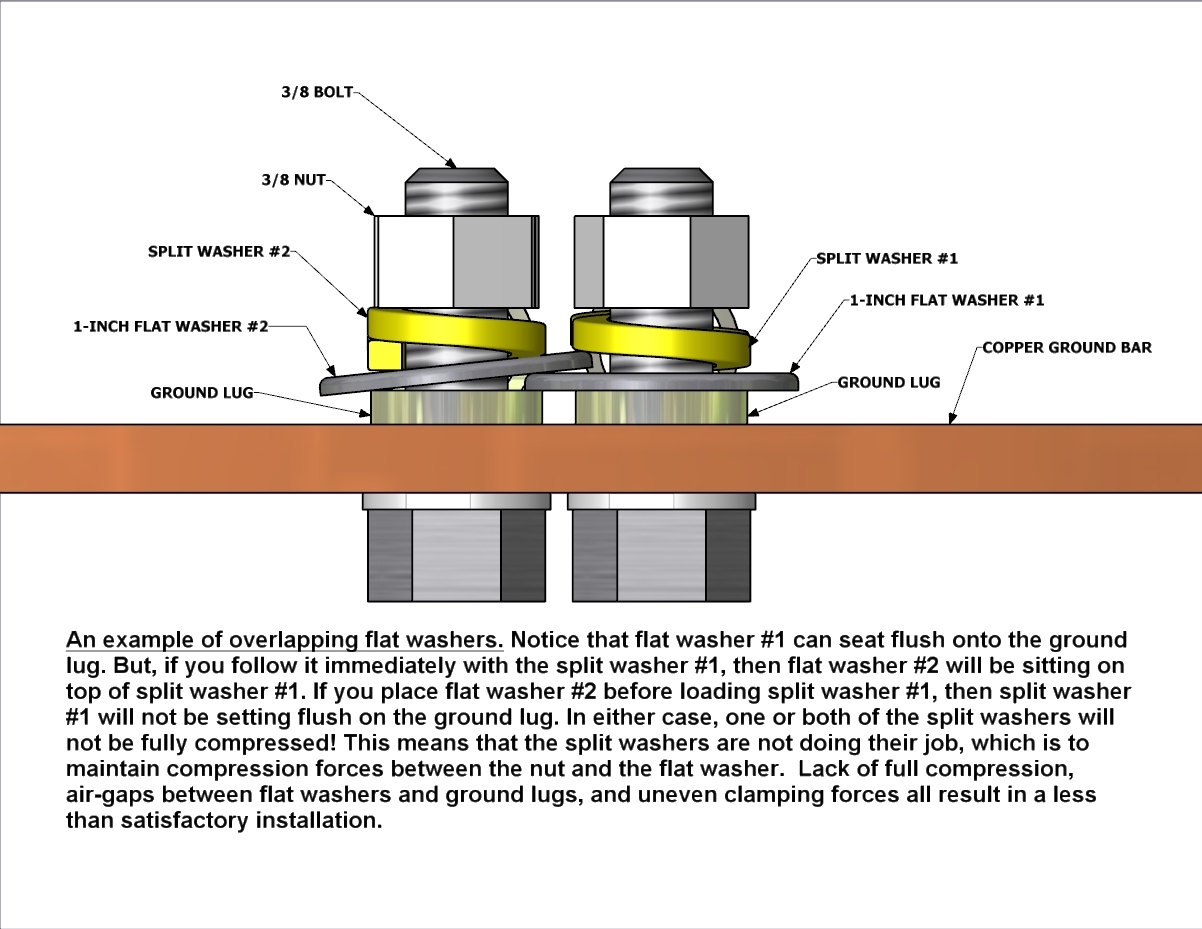

How To Use Belleville Washers Correctly. To keep bolted connections tight, we can choose from several methods. The most common is the insertion of a locking device between the rotating part (nut) and the parts being fastened (i.e., bus bars). That locking device often is a split-ring lockwasher. Such a device does not meet all locking device ...

Came here because I wanted to know more about the use of split ring lock washers. I had seen elsewhere that this type of lock washer was ineffective. What a surprise! Have been using them all my life. The order of jam nut and standard nut was a surprise too. Have been using them in the opposite sequence as long as I can remember.

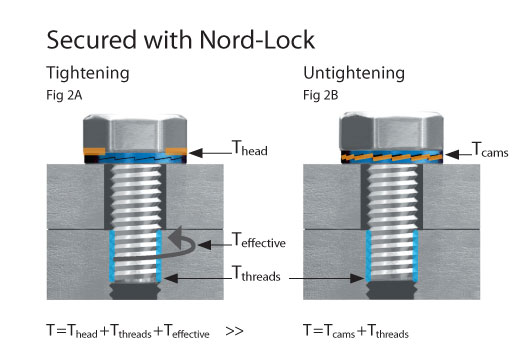

In this animated video, we explain the principle behind the Nord-Lock washers. Our original wedge-locking technology secures bolted joints, even when exposed...

Step 1 Place the lock nut against the threaded end of the bolt, just as you would place an ordinary nut. Make sure that if the nut has a raised center portion this faces out; the flat surface of the locking nut should sit flush against the work surface once tightened. Step 2 Hand-tighten the lock nut until it's securely threaded on to the bolt.

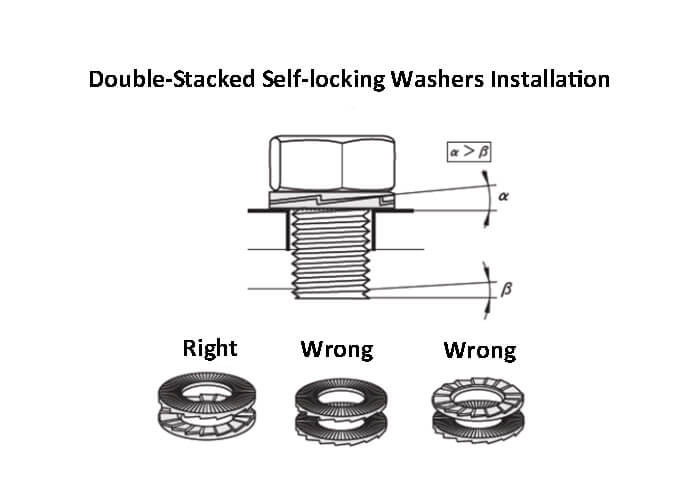

A split lock washer, also known as a helical spring washer, is the most common form of lock washer. Instead of using grooves, it operates more like a spring, holding the threaded fastener in place with friction. Use a split lock on a small, low-intensity job, since bigger loads will flatten the washer and make it useless.

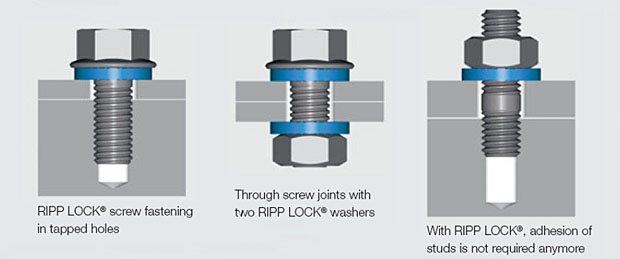

The outer diameter of regular Nord-Lock washers is designed for counterbore holes according to DIN 974, i.e. the washers fit under the head of standard bolts. Through-holes As for all locking washers, through-holes require two pairs of Nord-Lock washers - one pair for securing the bolt and a second pair for securing the nut.

Particularly suitable for dynamic loads - including when using lubricants; Can be re-used; Very easy to install and remove (wedge lock washers are supplied as a pre-assembled pair) Also suitable for high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts

However general installation guidelines for lock washers will help you to choose what type of lock washer to use on your next project. Advertisement Step 1 Place an external tooth lock washer over the threads of a bolt or screw larger than 1/2-inch diameter. The head of the fastener should cover the teeth on the external lock washer.

Lock washer. Flat washer. Nut. The lock washer is used to basically press into the material to grip onto it. The flat washer is used to create an even distribution of pressure from the nut. Both also create a larger holding surface for the nut and bolt to connect everything.

The combination for your lock is either: - Placed on the back of your lock OR - Handed out to you by your school The combination is made up of three numbers - When entering your combination, you must enter the numbers in the order shown on the combination tag. The combination for this lock is: 38-16-22

Loose bolts can lead to all kinds of problems in any application. Vibrations are one of the most well-known causes of loose fasteners. So fasteners were made...

Lawnmower manufacturers use screw-on nuts, lock washers and retaining pins to secure mower wheels. Occasionally, it becomes necessary to remove a wheel, perhaps to change it or in the case of a ...

When you get the world of washers, you cannot deny the convenience they give you when you need to repair your household tools.However, many people, including myself, become confused when attempting to use bolt, nuts, and lock washers - since the differences between the two washers is hard to tell.

0 Response to "39 how to use lock washers diagram"

Post a Comment