36 fishbone diagram quality improvement

A Technology-based Quality Improvement Approach to ... Purpose/Objectives: Communication failures are the root cause of >70% of sentinel events. Errors in nurse-physician communication particularly increase the risk of patient morbidity and mortality. Our global aim was to improve nurse-physician interprofessional communication and situational awareness. Our SMART aim was to increase resident and nursing perceived awareness of 3 handoff components ... 9 Steps For Constructing The Fishbone Diagram Step 1 in constructing a Fishbone Diagram The first step is to agree on the topic or problem to be analyzed. For example, a quality characteristic that needs improvement. We are supposed to use data specifically to describe the problem. Step 2 in constructing a Fishbone Diagram

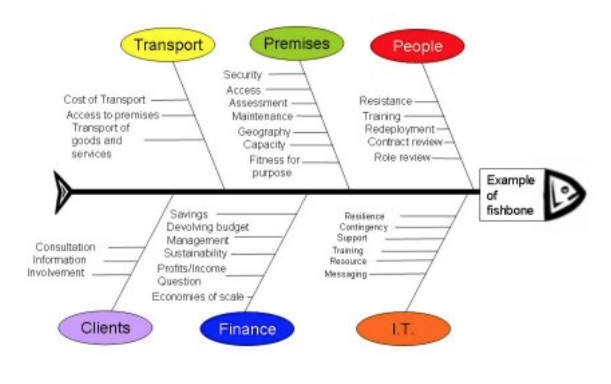

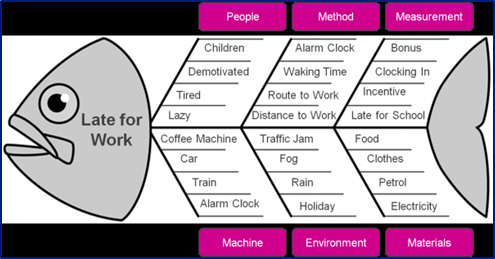

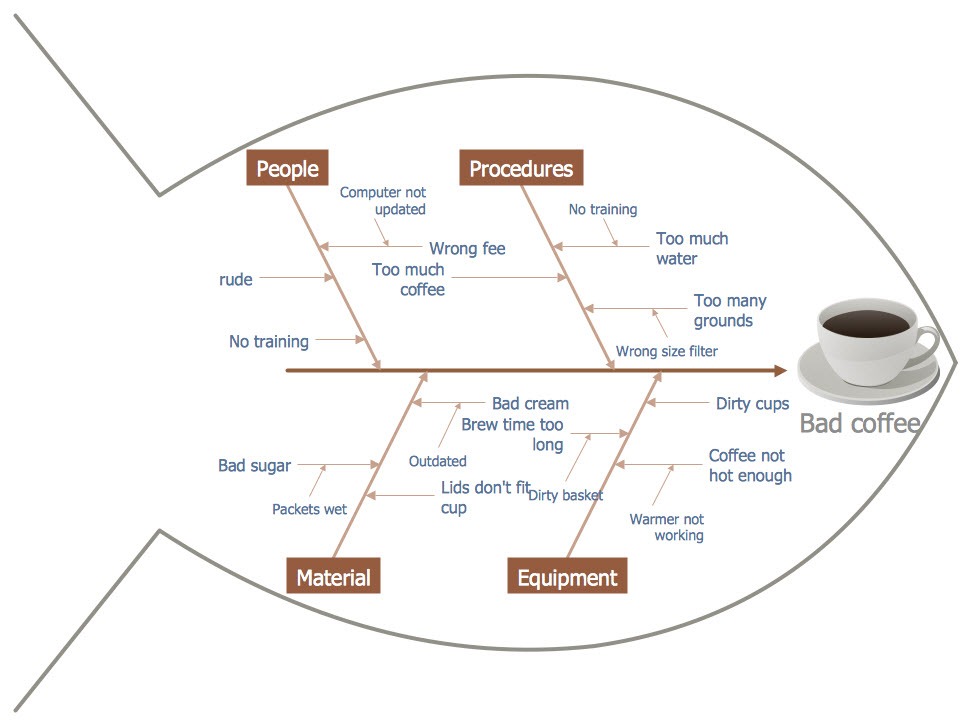

Benefits of Fishbone Diagrams - Edraw - Edrawsoft The fishbone diagram, or the cause and effect diagram, is a simple graphic presentation that displays all the possible causes of a problem. It is also called the Ishikawa diagram. Here is a fishbone diagram example depicting the causes of low market share from five perspectives: customer, advertisement, personnel, competitor, and sales channel.

Fishbone diagram quality improvement

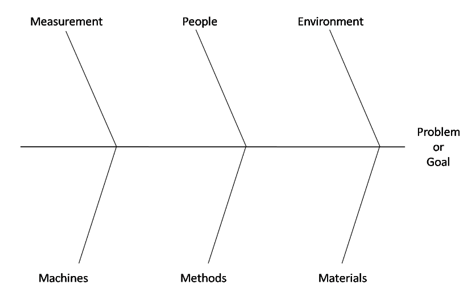

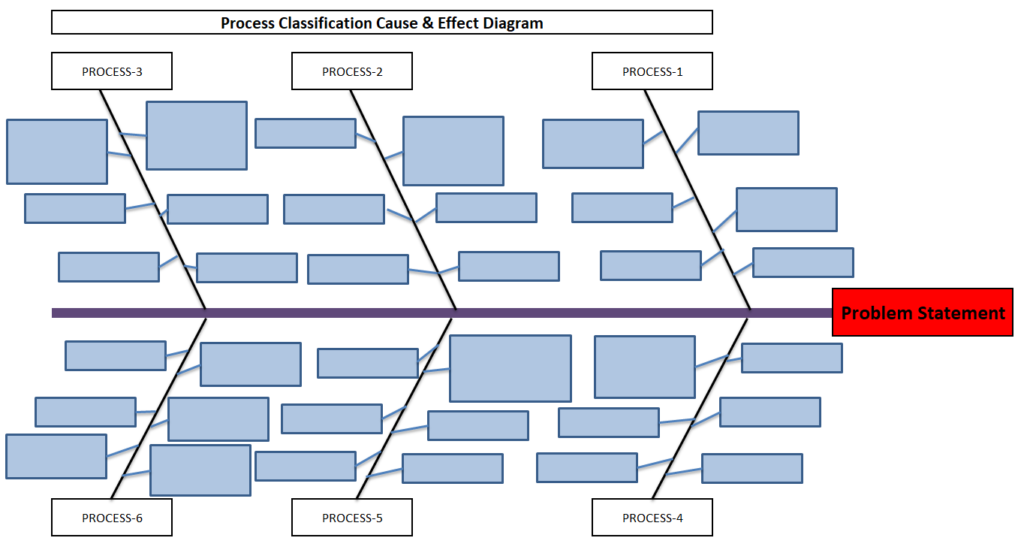

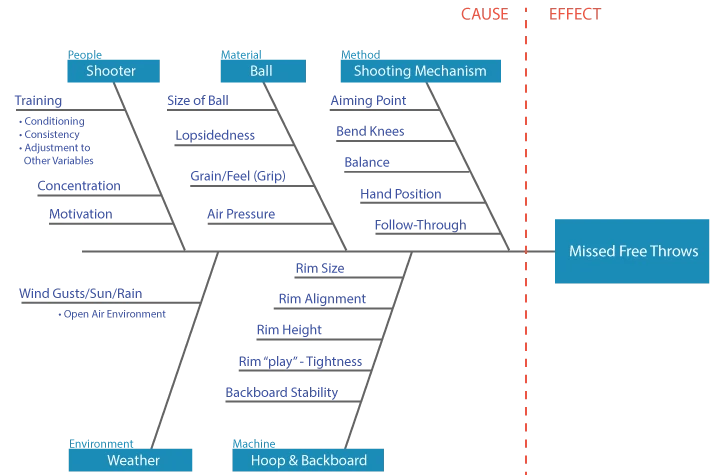

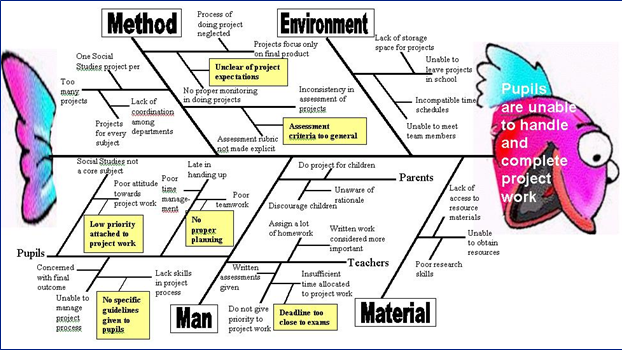

Quality Improvement Methodologies Increase Autologous ... Fishbone diagram, key driver diagram, Plan-Do-Study-Act (PDSA) cycles, and data collection forms were used throughout this QI process to track and guide progress regarding CS waste. Of patients under 6 kg (n = 5), 80% had wasted CS blood before interventions, whereas those patients larger than 36 kg (n = 8) had 25% wasted CS before interventions. How to Create a Fishbone Diagram for Medical Diagnosis ... Fishbone diagrams have many benefits that can be utilized in health care settings. Aside from being easy to understand and analyze, they are useful in: Stimulating brainstorming and creative thinking Identifying various causes behind a problem Linking causes to an effect Solving problems Prioritizing and addressing root causes Fishbone Diagram: A Supertool to Understand Problems ... By Dianna Deeney | June 30, 2021 A Fishbone Diagram is named for its looks because it resembles the bones of a fish drawn on paper. Its less creative names are Cause-and-Effect Diagram and Ishikawa Diagram. It's popularly known to help with root cause analysis. But, we can also use it to help with goals and to evaluate a potential solution.

Fishbone diagram quality improvement. Write a 1,050-word action plan for your Quality ... Assignment Content Quality measures are methods to appraise health care by using standards. The purpose of these measures are to make sure all patients get the right care at the appropriate time. Refer back to your Fishbone Diagram in the Quality Improvement: Preventable Errors assignment in Week 1 and select two areas of improvement you […] Read "The Case of Mr. Baum (PDF)."Create a fishbone ... Read "The Case of Mr. Baum (PDF)."Create a fishbone diagram of this case for the Quality Improvement Team. You may download and use the Fishbone Template (Word). Teach your team to solve their own problems. Fishbones or causal diagrams were popularized by Kaoru Ishikawa in the 1960s that show the potential causes of a specific event. Applications: Common uses of the diagram are process issues, product... What is Process Improvement? Activity network diagram: Listing of the appropriate sequence or schedule for a set of tasks and related subtasks. Other forms of visual representation include fishbone diagrams, histogram charts, scatter diagrams and pareto charts. Methodologies for Business Process Improvement. Several methodologies are now available for business process ...

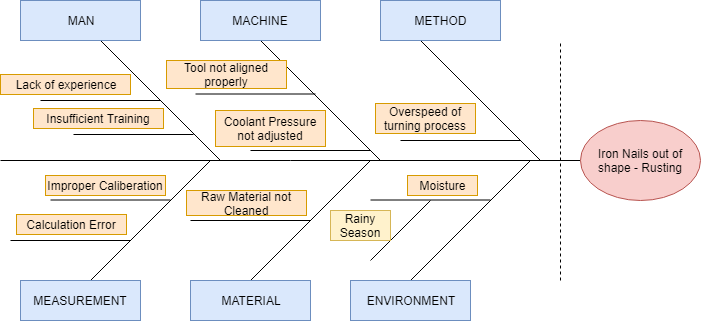

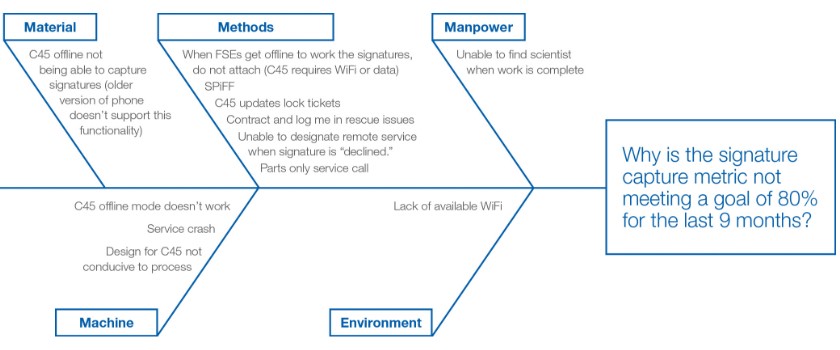

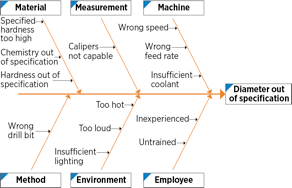

Seven Basic Tools of Quality for Process Improvement ... Hence, the seven quality control tools of quality management are believed to be the gold standards for process improvement. Here are the 7 Basic Quality Control (QC) Tools for Process Improvement in quality management: Cause-and-effect diagrams (Fishbone or Ishikawa diagram) Scatter diagrams Histograms Control charts Pareto charts Check sheets Fishbone Diagram Hospital Length Of Stay - possible causes ... 26 fishbone diagram quality improvement wiring database 2020. Fishbone Diagram Hospital Length Of Stay. Here are a number of highest rated Fishbone Diagram Hospital Length Of Stay pictures on internet. We identified it from well-behaved source. Its submitted by organization in the best field. We allow this kind of Fishbone Diagram Hospital ... Performance and Quality Improvement in a Foundry Industry ... At this stage, the factors disturbing the motor casing quality can be recognized using a fishbone diagram. The root causes were identified, and a detailed fishbone diagram was drawn. Step 3 Applying FDM to identify the critical factors The critical factors were recognized using FDM. Improving Care for Childhood Obesity: A Quality ... Based on our Fishbone diagram, we selected providing education as the first PDSA to address providers' lack of knowledge. We chose all subsequent PDSAs to address the provider-identified barriers when we fed-back data to them. We have listed these in the "Act" section of the PDSA in Table 1. Table 1. Details of 5 PDSA Cycles Conducted by QI Team

Understanding the Ishikawa diagram - Creately Blog When it comes to quality improvement, most of us are probably aware of some of the most effective tools, namely the control chart, run chart, histogram, scatter diagram and flowchart.But IMO the father of quality management, Dr. Kaoru Ishikawa, has to be credited with the mother of all quality improvement tools - the Ishikawa diagram, which falls under the larger cause and effect diagram ... Read "The Case of Mr. Baum (PDF)."Create a fishbone ... steroids and inhaled bronchodilators, which resulted in a gradual improvement in his. respiratory symptoms. Nurses also gave him IV fluids for the issue with his kidneys, which slowly resolved. Mr. Baum was steadily improving, so it seemed this visit to the. hospital would be one of his shorter ones. Think Insights - Fishbone Diagram: How to find the root ... The Fishbone diagram was developed by Dr. Kaoru Ishikawa, a Japanese quality control statistician in the 1960s, with an aim to aid employees avoid solutions that merely address the symptoms of a much larger problem.. Objective. In our day-to-day lives as well as professional careers and businesses, no matter what line we are in, sometimes things get wrong, and we are faced with problems and ... 7 Basic Quality Tools for Improvement | Templates Attached ... Cause and Effect (Fish Bone) Diagrams. The Father in 'Quality Circles' Professor K. Ishikawa, was the first to develop the Cause and Effect Analysis in the 1960s. Brainstorming is done, and then a diagram is developed after all of the possible causes of a problem. In this way, a thorough analysis is done of any specifics of the situation.

A Quality Improvement Approach to Early Patient Discharge ... the current literature indicates that quality improvement (qi) methodology and efficient and collaborative nurse-physician rounding can decrease the incidence of delayed patient discharges, improve patient care, and increase hospital bed availability. 15 - 19 lean six sigma is a process-focused qi methodology that emphasizes process optimization …

Free Fishbone Diagram Templates for Word, PowerPoint, PDF The fishbone diagram is a simple yet very effective tool that improves a process and a commodity's quality. When an organization is persistent with implementing this visual representation of cause-and-effect relationships, it can be proactive in addressing its problems quickly and effectively.

Quality Tools & Templates - List of Healthcare Tools | ASQ Fishbone (cause-and-effect) diagram (Excel) Analyze process dispersion with this simple, visual tool. The resulting diagram illustrates the main causes and subcauses leading to an effect (symptom). Flowchart (Excel) Create a graphical representation of the steps in a process to better understand it and reveal opportunities for improvement.

Fishbone Diagram Templates | AKA Cause and Effect or ... Fishbone (aka Cause and effect/Ishikawa) diagrams are great for analyzing processes and identifying defects in them. They are a great way to visualize causes and their effects. Fishbone diagrams are used in many industries but primarily they're used in manufacturing, sales, and marketing. Below are some fishbone diagram templates from our diagramming community.

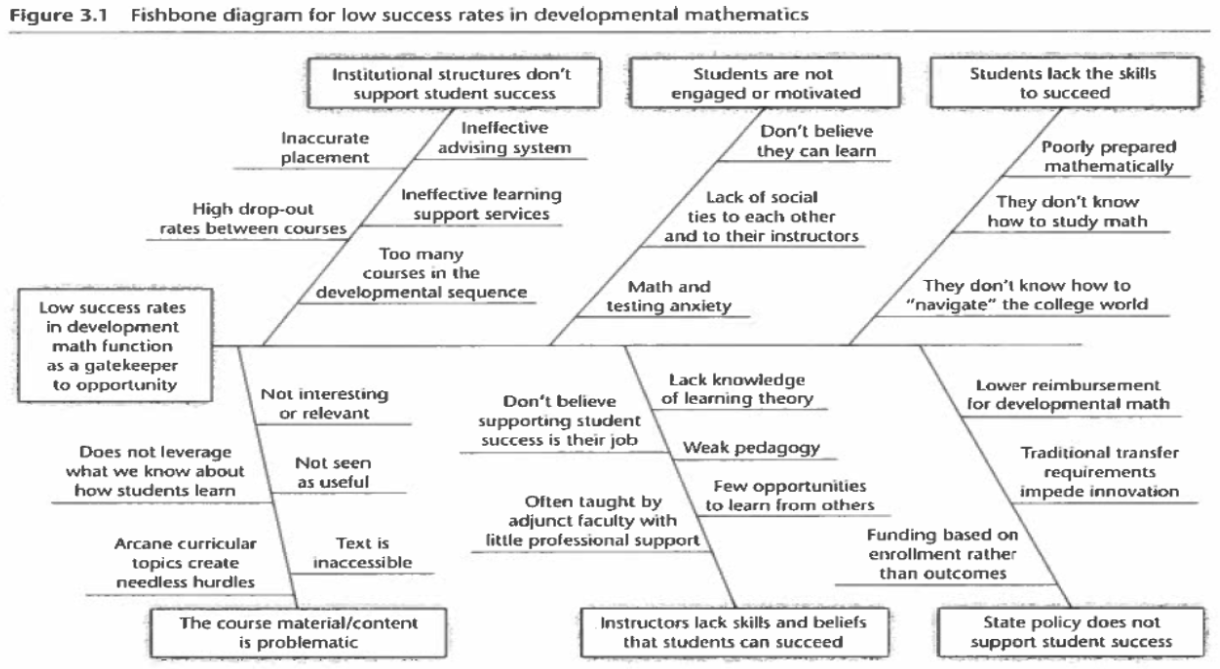

Fishbone Diagram Example 2. Understand Fishbone Diagram Example One of the seven quality circles (QC) tools is the fishbone diagram. It aids in the visualization of probable reasons to identify the underlying cause of an issue, and it aids in the detection, analysis, and improvement of quality concerns. The below fishbone diagram example is commonly used in product ...

Week 5 Resources - DHA-7005 - LibGuides at Northcentral ... The American society for quality ASQ. (2020). Fishbone diagram. This society, originally develop by quality improvement leaders, such as Demming provides information on quality improvement strategies and tools.

Case study of Mr. Baum Create a fishbone diagram of this ... Create a fishbone diagram of this case for the Quality Improvement Team. You may download and use the Fishbone Template (Word). (10 points) Identify process improvements that could reduce the likelihood that these errors/failures will recur in the future. (10 points) The Case of Mr. Baum Quality Improvement Case Study—Fishbone Analysis)

Using Fishbone Diagrams for Complex Problems - Venngage Fishbone diagrams are also known as Ishikawa diagrams, named after Professor Kaoru Ishikawa who was a pioneer in the field of quality management and who created this unique visualization. Although they were initially used for quality improvement, today fishbone diagrams can be helpful for all kinds of problem-solving.

Fishbone Diagram: A Supertool to Understand Problems ... By Dianna Deeney | June 30, 2021 A Fishbone Diagram is named for its looks because it resembles the bones of a fish drawn on paper. Its less creative names are Cause-and-Effect Diagram and Ishikawa Diagram. It's popularly known to help with root cause analysis. But, we can also use it to help with goals and to evaluate a potential solution.

How to Create a Fishbone Diagram for Medical Diagnosis ... Fishbone diagrams have many benefits that can be utilized in health care settings. Aside from being easy to understand and analyze, they are useful in: Stimulating brainstorming and creative thinking Identifying various causes behind a problem Linking causes to an effect Solving problems Prioritizing and addressing root causes

Quality Improvement Methodologies Increase Autologous ... Fishbone diagram, key driver diagram, Plan-Do-Study-Act (PDSA) cycles, and data collection forms were used throughout this QI process to track and guide progress regarding CS waste. Of patients under 6 kg (n = 5), 80% had wasted CS blood before interventions, whereas those patients larger than 36 kg (n = 8) had 25% wasted CS before interventions.

0 Response to "36 fishbone diagram quality improvement"

Post a Comment