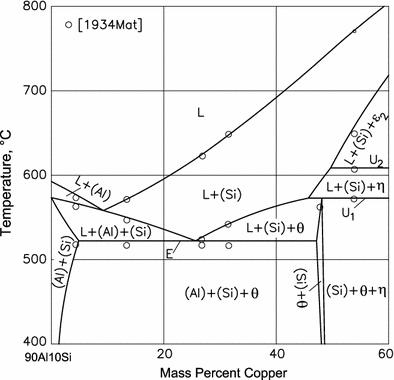

35 copper aluminum phase diagram

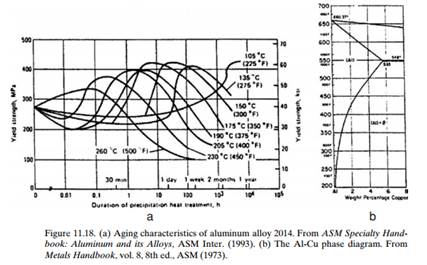

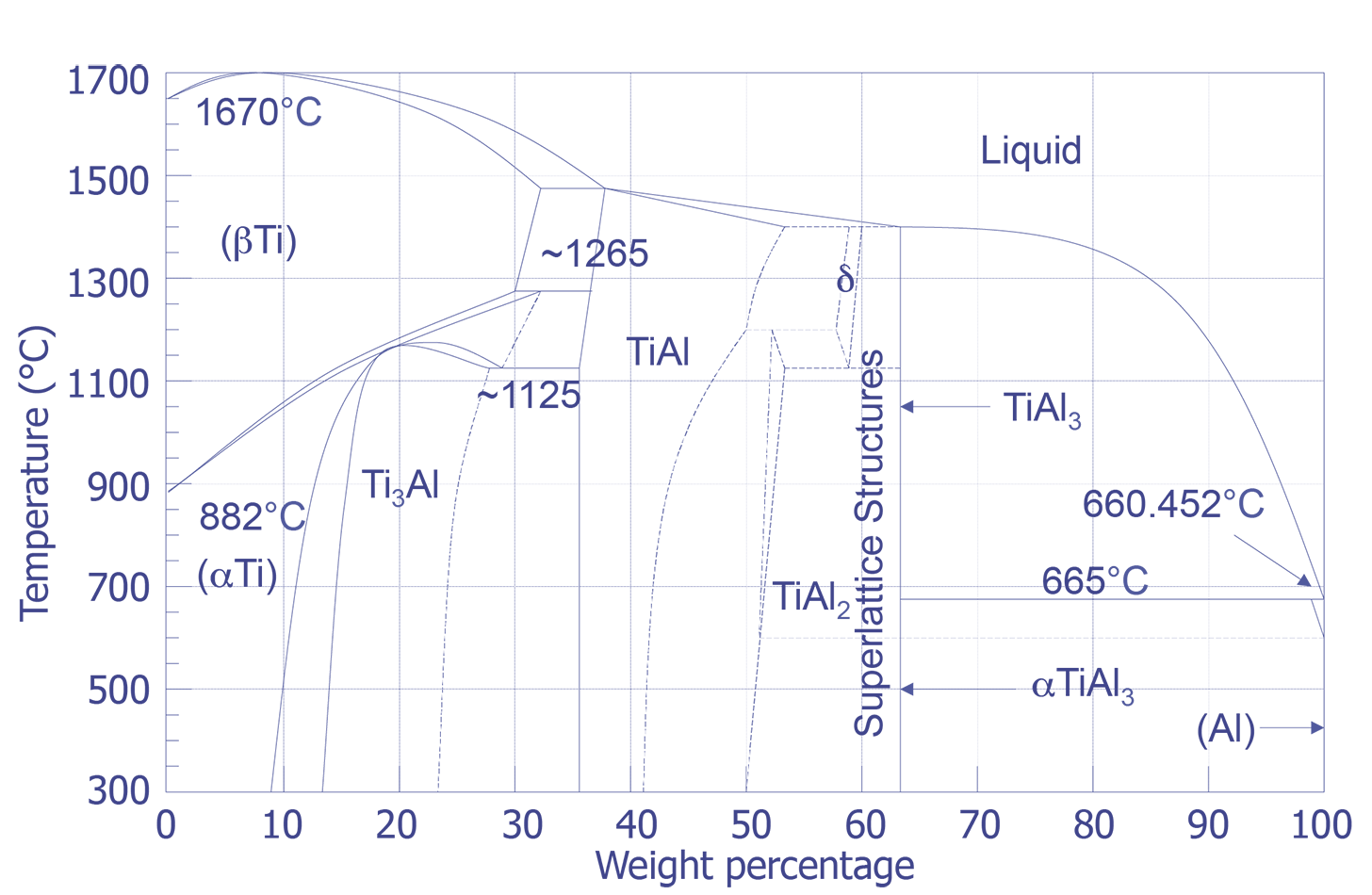

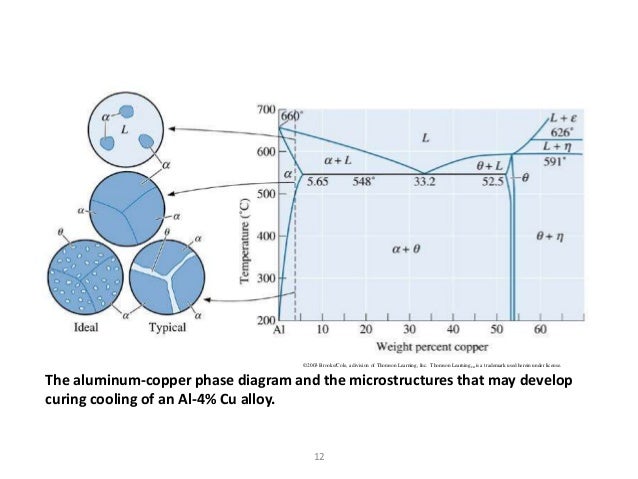

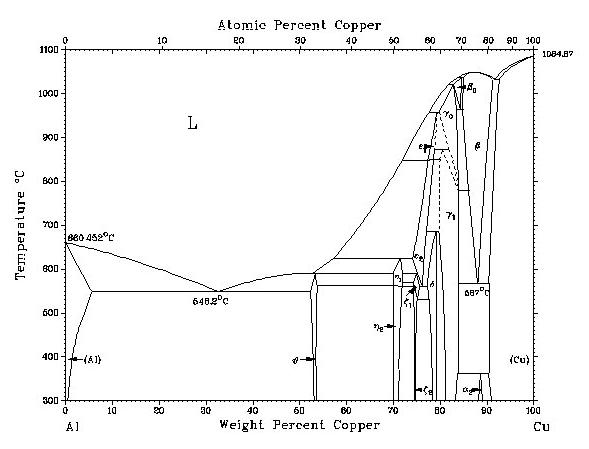

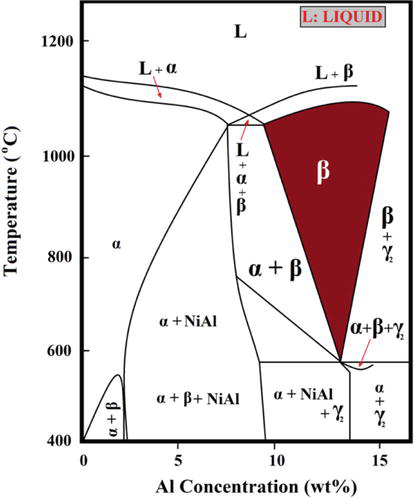

Chapter 9: Phase Diagrams Phase A Phase B Nickel atom Copper atom. Chapter 9 - 2 Phase Equilibria: Solubility Limit Introduction ... Aluminum-Copper Alloy Components and Phases α (darker phase) β (lighter phase) Adapted from chapter-opening photograph, Chapter 9, Callister 3e. The copper rich end of the copper-aluminum binary phase diagram is shown. The vertical red line shows the composition: Cu-7 wt % Al. This alloy has the single phase a-structure, that is a substitutional solid solution of aluminum in the fcc copper matrix.This composition has a melting temperature of about 1030 C.

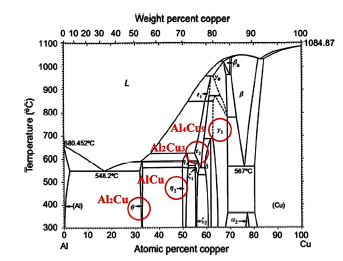

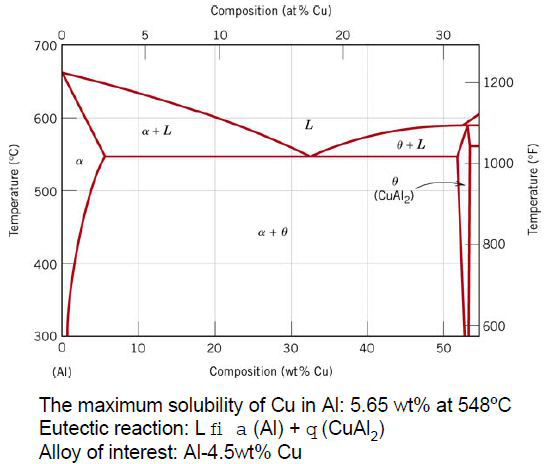

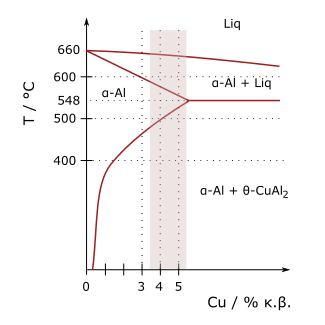

Aluminium-copper phase diagram, reproduced with the permission of Jud Ready of the Georgia Tech. Joint Student Chapter of ASM/TMS. Only the CuAl 2 are within the reach of optical microscopy. Specimen M24, which is an Al-4Cu wt% alloy, is in a grossly overaged condition to facilitate obsevations.

Copper aluminum phase diagram

Copper-aluminums (left side of the phase diagram of Fig. 4.5), are also known as aluminum bronzes. Al, in substitutional solid solution in the Cu crystalline lattice, simultaneously provides an improvement in the mechanical strength of Cu and an increase in its resistance to corrosion to weak corrosives, specifically in acid environments ... The Al-Cu phase diagram is split at around 54wt%Cuby a particular phase. the two parts of the diagram can be considered separately. The diagram up to the 54% point is very similar to the "standard" phase diagram. When a phase diagram, such as this one, has an intermetallic 1203.01 Introduction to binary and ternary phase diagrams 1203.01.01 Background - single and two component systems Super-pure aluminium is a single component material, that is, the only material is aluminium: below its melting point it is a single phase solid (crystalline aluminium

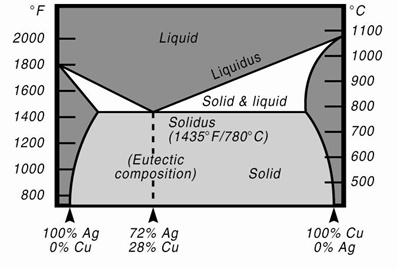

Copper aluminum phase diagram. The phase diagram for the simple system aluminum copper is drawn below. Answer the following questions by referring to this diagram. A. How many phases will be present if an aluminum-copper mixture containing 80% copper is heated to 1000oC? B. If the system described in (A) is slowly cooled, at what temperature will a solid start to appear? Publisher Summary. This chapter examines the phase composition of alloys that contain magnesium and silicon in the absence of copper. It mentions that the aluminum-magnesium-silicon (Al-Mg-Si) phase diagram can be used for the analysis of many wrought alloys of 6XXX-series and casting alloys of the 356.0 type, provided the concentration of iron impurity is low. Solution for 3. The phase diagram for the simple system aluminum copper is drawn below. Answer the following questions by referring to this diagram. 200 D00 D.… Eutectic phase diagram for a silver-copper system. 2800 2600 2400 2200 2000 1800 1600 MgO CaO 20 40 60 80 100 0 C) L MgO ss + L MgO ss CaO ss + L CaO ss MgO ss + CaO ss Wt % Eutetic phase diagram for MgO-CaO system. Temperature (Lecture 19 – Binary phase diagrams 4 of 16 11/23/05

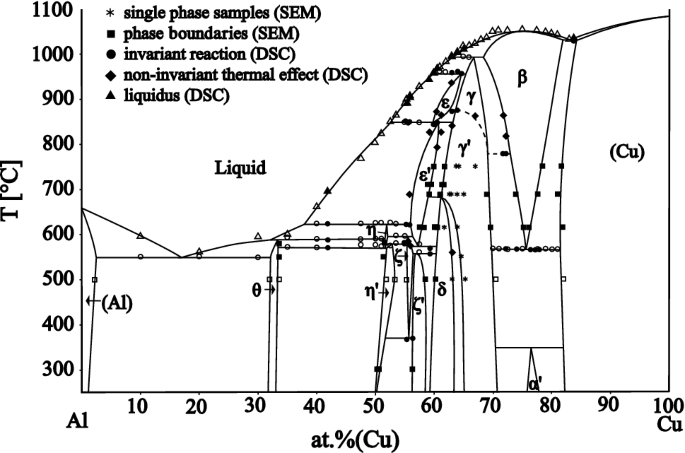

at the left of the diagram where the alloy is in solid solution (phase ), a face centred cubic structure like copper. For the typical alloy CuBe1.9 (1.8 to 2% of beryllium) the alloy is in the phase between 720°C and 860°C. For industrial purposes the solution heat treatment is done between 750° and 800°C. By rapidly cooling the Feb 06, 2022 · Here are a number of highest rated Aluminium Copper Phase Diagram pictures on internet. We identified it from honorable source. Its submitted by dispensation in the best field. We give a positive response this kind of Aluminium Copper Phase Diagram graphic could possibly be the most trending topic past we ration it in google help or facebook. by S Amer · 2020 · Cited by 12 — (Al,Cu,Mn,Er) phase with possible composition Al25Cu4Mn2Er was ... A.V. The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner. Abstract. A critical assessment is given of the phase equilibria of the AI-Cu system. In the first section, the stable equilibrium diagram is constructed. In the second section, metastable and constrained equilibria are considered. These include metastable solvus curves of the AI-rich side of the diagram; on the Cu-rich side, transformations ...

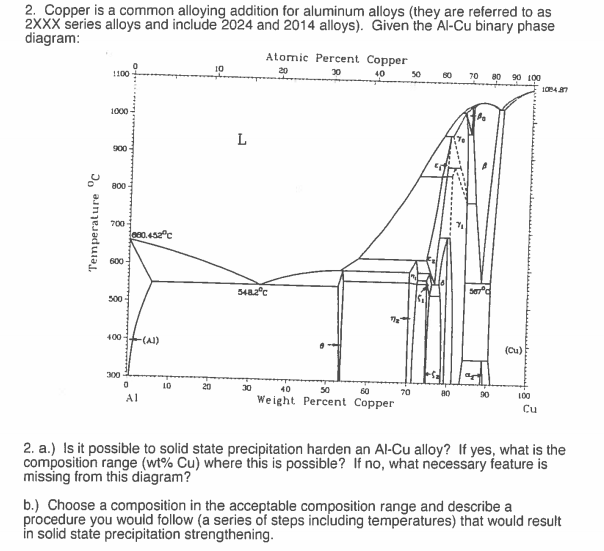

Copper in Powder Metallurgy. A. Phase Diagrams 1. Iron-Copper System The iron-copper phase diagram, taken from Hansen,3 is presented in Figure 1. Hansen3 also gives a thorough review of the work done on the system up to 1957. A review of more recent work, up to 1963 was done by . Elliott~ The most recent version of the phase diagram The following phase diagram shows the alpha and beta phases of aluminium bronze in relation to copper to aluminium ratio. The freezing point rapidly decreases as more aluminium is diffused with the copper. Up-to 8%Al there is a single α phase and then ˃8%Al there is a α + β phase which is stronger than the α phase but less ductile. 1*2/Introduction to Alloy Phase Diagrams magnesium, and manganese. These substances constitute the components comprising the system and should not be confused with the various phases found within the system. A system, how- ever, also can consist of a single component, such as an element or compound. Phase Diagrams. Aug 14, 2021 · Aluminum-Copper Phase Diagram Another commonly used phase diagram is the aluminum-copper phase diagram, which is useful for understanding precipitation strengthening in Al-Cu alloys. The amount of copper present in an alloy is plotted on the x-axis. The phase fields of interest are the Al, θ, and Al+θ phase fields on the left hand side.

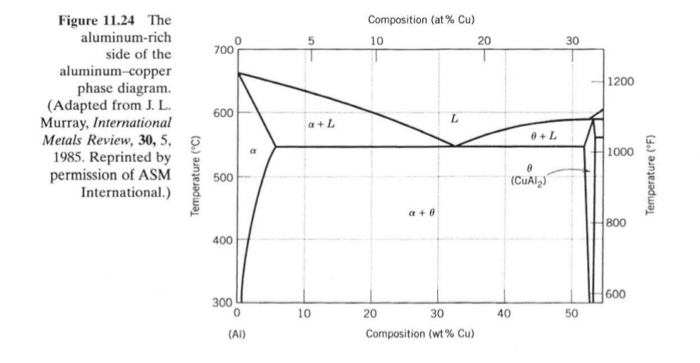

Copper, % Portion of aluminum-copper binary phase diagram. Temperature ranges for annealing, precipitation heat Fig 1 treating, and solution heat treating are indicated. The range for solution treating is below the eutectic melting point of 548 °C (1018 °F) at 5.65 wt% Cu.

S. Westman, Phase Analysis at 660°C of the Gamma Region of the Copper-Aluminum System,Acta Chem. Scand., 19, p 2369–2372 (1965). Article Google Scholar 17.

A phase diagrams show what phases exist at equilibrium and what phase transformations we can expect when we change one of the parameters of the system. Real materials are almost always mixtures of different elements rather than pure substances: in addition to T and ... Copper - Silver phase diagram

phase diagram of Aluminum-Zinc in the aluminum-rich region in Figure 8-1. Figure 8-1: Schematic phase diagram for an age hardenable alloy. When the aluminum-zinc alloy of less than 5-6 wt% zinc is heated to temperature just above the solvus line, only one phase is thermodynamically stable. Other solid phases dissolve. This process is called

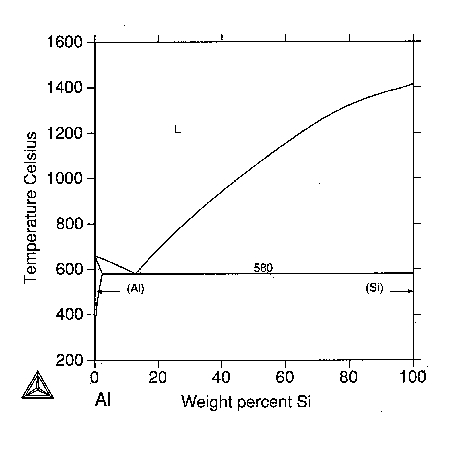

copper (5.7 wt%) and silicon (1.65 wt%). We shall see that the addition of these elements can radically alter the properties of pure aluminium. Typical Phase Diagrams Typical eutectic and a peritectic phase diagrams are illustrated in Fig. 2; these two forms describe the vast majority of phase diagrams for aluminium alloys.

The phase diagram for Aluminium-copper system [21] From the phase diagram above, the eutectic reaction occurs at a temperature of 548 0 C and 33.2%wt Cu ...

Aluminum •"Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust.

H. Watanabe, T. Okamoto, N. Kono and M. Kato, Phase Diagram in the Aluminum Corner of the Aluminum-Copper-Indium Alloy System,J. Jpn. Inst. Light Met. 24, p 418-426 (1974) in Japanese; see alsoMet. Abstr. Light Metals and Alloys, 10, p 83-89 (1973-1974). See Fig. 5 to 7. Google Scholar 4.

Copper Aluminum Alloys This Al-Cu phase diagram shown only goes up to ca 60%, by weight, of Copper. and is “split” at around 54wt%Cu by a particular phase. This "split" means that the two parts of the diagram must be considered separately. The diagram up to the 54% point is very similar to the "standard" phase diagram. Intermetallic phases are

Phase Diagram of Copper-Aluminum Here is the Aluminum - Copper phase diagram. Yes, it is quite complicated - but only if you alloy more then about 53 at% copper. The aluminum - Al2Cu phase diagram; i.e. the part left to the 53 at% Cu, is about as simple as you can have it for two atoms that cannot mix atomically at any large ratio.

The phase diagram shown is a partial diagram for the Aluminum-Copper system showing the aluminum rich end. The composition of a typical structural alloy is ...

This representation is called a phase diagram. The phase diagrams of some binary systems relevant to bronze show the behavior of alloying elements that typically results in one of the three cases mentioned previously. The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2).

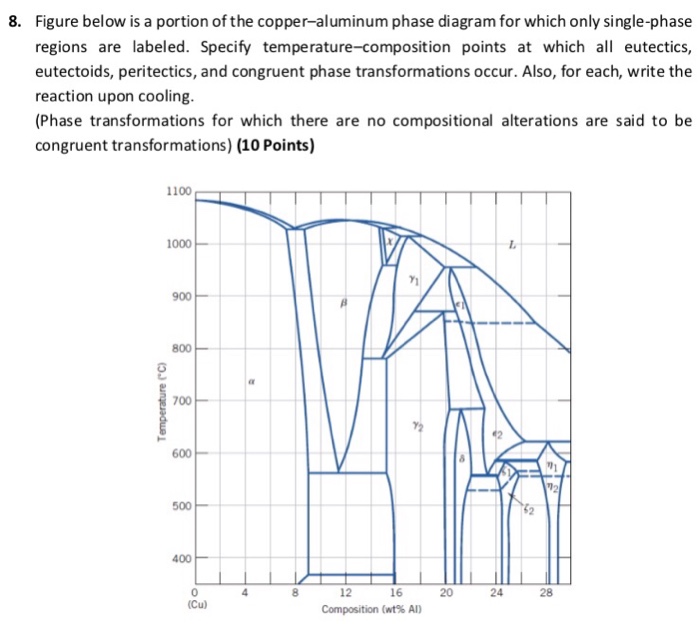

Figure below is a portion of the copper-aluminum phase diagram for which only single-phase regions are labeled. Specify temperature composition points at which al eutectics, eutectoids, peritectics, and congruent phase transformations occur. Also, for each, write the reaction upon cooling. (Phase transformations for which there are no compositional

The CueAl binary phase diagram suggests the possibility of formation of γ 1 (Cu 9 Al 4 ), δ (Cu 3 Al 2 ), ζ 2 (Cu 4 Al 3 ), η 2 (CuAl), and θ (CuAl 2 ) in the temperature range below 300°C ...

The phase diagram of an aluminum (Al)-copper (Cu) alloy is shown in Figure 3. (a) State the eutectic composition. (b) For a 1.8 kg Al and 0.2 kg Cu alloy at 600°C (1112°F), cite the (i) Phase(s) present (ii) Composition(s) of the phase(s) (iii) Mass fraction(s) of the phase(s)? (c) For a 55 wt% Al-45 wt% Cu alloy that is slowly cooled, draw the

1203.01 Introduction to binary and ternary phase diagrams 1203.01.01 Background - single and two component systems Super-pure aluminium is a single component material, that is, the only material is aluminium: below its melting point it is a single phase solid (crystalline aluminium

The Al-Cu phase diagram is split at around 54wt%Cuby a particular phase. the two parts of the diagram can be considered separately. The diagram up to the 54% point is very similar to the "standard" phase diagram. When a phase diagram, such as this one, has an intermetallic

Copper-aluminums (left side of the phase diagram of Fig. 4.5), are also known as aluminum bronzes. Al, in substitutional solid solution in the Cu crystalline lattice, simultaneously provides an improvement in the mechanical strength of Cu and an increase in its resistance to corrosion to weak corrosives, specifically in acid environments ...

0 Response to "35 copper aluminum phase diagram"

Post a Comment